Project H2

Development of a hydrogen powertrain for a Swiss Lightwing AC4

Cellsius' vision is to be able to operate aircraft in the future in a climate-neutral, efficient and sustainable manner. To this end, Cellsius Project H2 is researching an alternative hydrogen powertrain that will power a small aircraft in the future!

-

2 h +

Our hydrogen propulsion system should enable a cruise flight of over two hours.

-

250 km +

Our propulsion system allows us to fly for more than 250 km.

-

0g CO2

A hydrogen aircraft emits no harmful CO2.

Implementation

Our powertrain consists of many components that together can get an airplane into the air.

To make this a reality, we develop a large part of our components ourselves, tailored to our requirements.

Thus, our developments range from the design of pressure tanks, to the development of our own

High-performance inverter up to the own electric motor.

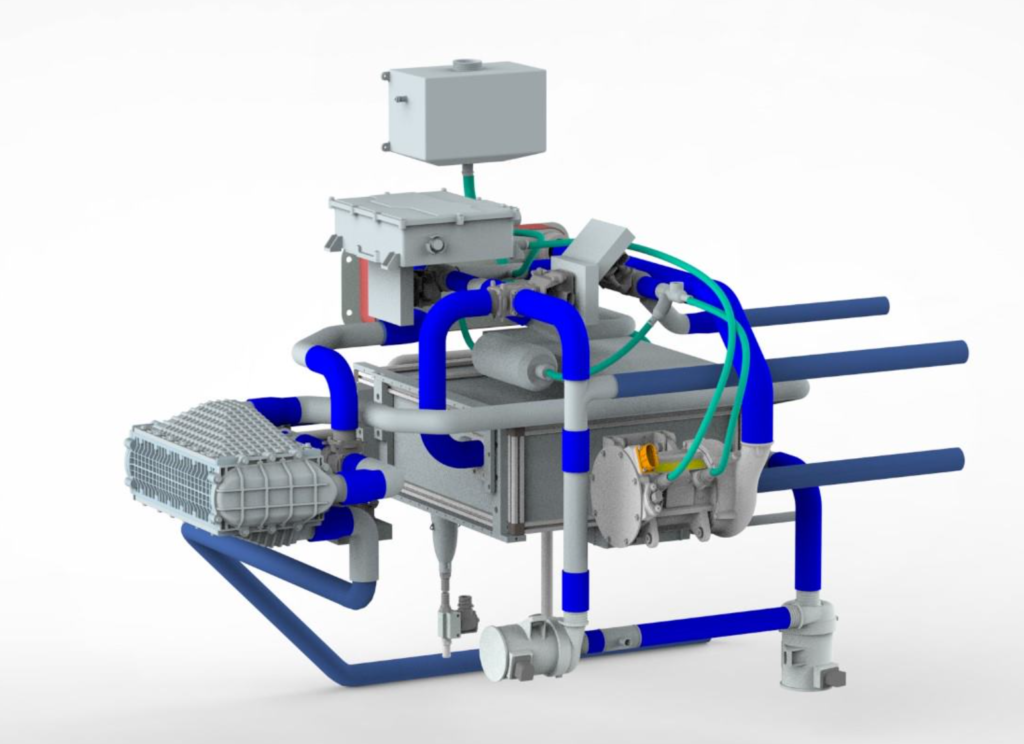

The System

Our unique powertrain consists of many technical submodules, all of which must work together in an orderly fashion for our aircraft to take off.

We are happy to briefly present the components that are installed:

Power Electronics

Effizienz DC/DC: 95%

Effizienz Inverter: 98%

Flüssigkühlung

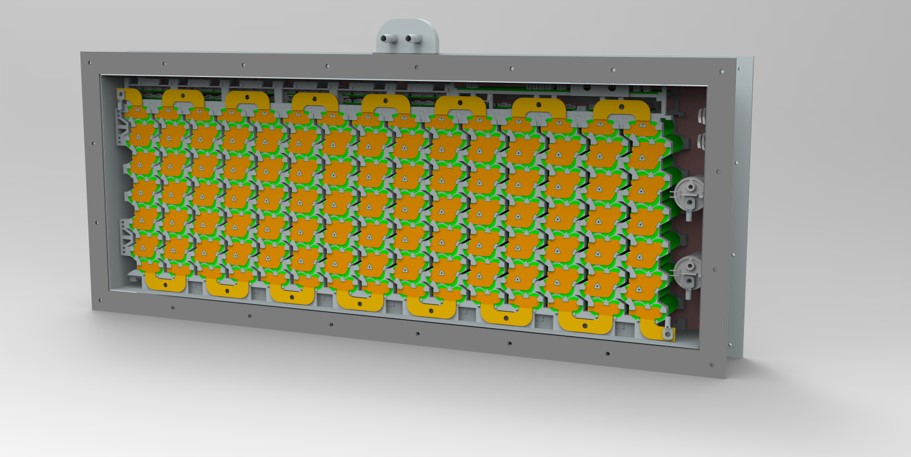

Battery

Kapazität: 5.8 kWh

Kont. Leistung: 35 kW

Spannung: 756 V

Motor

Leistung: 105 kW

Brennstoffzelle

Leistung: 100 kW

Gewicht: 120 kg

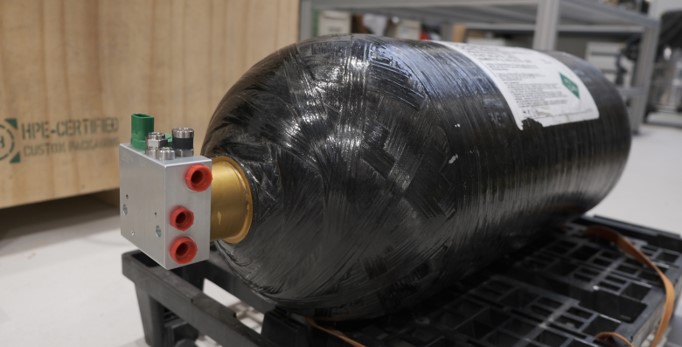

Drucktank

Tankgewicht: je 45 kg

Druck: 700 bar

Kapazität: je 2 kg

The Aircraft

Our new engine will be installed in a Swiss Lightwing AC4. Modifications will be made to the airframe so that it will fit perfectly.

The performance of our drivetrain is optimally matched to that of the AC4.

Fuel Cell System

The heart of our powertrain is a 68 kW hydrogen fuel cell. It produces the necessary electrical energy for flight.

Pressure Tanks

The hydrogen is carried in multiple high pressure tanks with 700 bar. These tanks allow a cruise fight for multiple hours.

Batteries

To absorb power peaks during take-off or a go-around, a battery module with a total capacity of 5.8 kWh is installed. The batteries are liquid-cooled and can be recharged in flight by the fuel cell.

Motor

Central to making our aircraft take off is an efficient and powerful electric motor. To optimally meet our requirements, we design and manufacture the radial flux motor ourselves, in partnership with e+a.

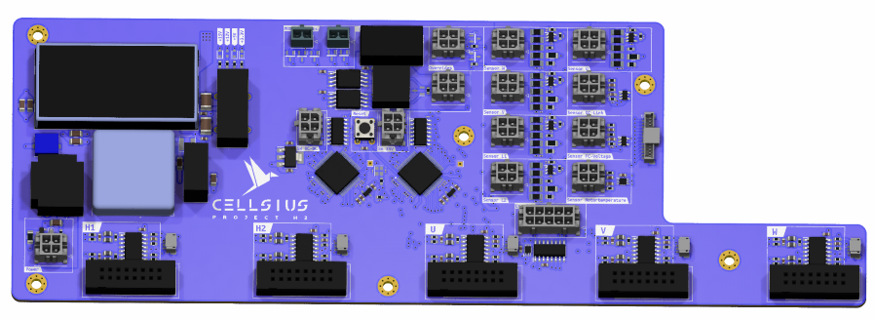

Power Electronics

For the operation of an AC motor with batteries and a fuel cell, an inverter and a DC/DC converter are essential. Both are developed inhouse, so that they fit perfectly to our system.

Timetable

Das diesjährige Fokusteam hat die Arbeit am Wasserstoffflugzeug aufgenommen.

Während des Besuchs bei der Light Wing AG hatten unsere Teammitglieder die Möglichkeit, das zukünftige Flugzeug zu besichtigen, in dem unser wasserstoffbetriebener Antriebsstrang zum Einsatz kommen wird. Es fanden auch einige technische Gespräche mit den Technikern von Light Wing statt. Die Arbeit hört nie auf 🙂

During the visit at Light Wing AG our team members had the chance to see the prospective hydrogen powered airplane which will host our powertrain. Also some technical talks with the engineers of Light Wing took place. Work never stops :)

Nach langer Planung ist endlich unser dritter Schiffscontainer in Dübendorf angekommen. Er wird verwendet um eine sichere Testumgebung für unser Wasserstoffsystem zu schaffen

Although many sensors and other components are still stuck somewhere between production and delivery, we were able to carry out some tests on 5 May, for example to control the cooling pump with different signals. Further tests will follow in the course of the next few weeks.

On a sunny spring morning, we set up our metal framework for the test stand outside the hangar. With the help of Item's aluminium profiles and grooved plates, we can later attach all the components directly and still be very flexible if there are any small changes.

In the longer time between the test phase in February and Review 3, we have made great progress. The current status is that all components are in the hangar or at least ordered and that we will soon be ready to carry out the first tests. The biggest point that will still occupy us now is the software and the control system.

The sensitive membrane of the fuel cell requires very precise values of temperature, mass flow and pressure of the air and hydrogen in the fuel cell. To obtain these values, we created a digital twin on Gamma Technologies. This model can later be used to design the various controllers using Simulink.

For the control and regulation of our system, we decided to develop our own main control unit. So we started to design a circuit board on a professional programm and after several weeks we were finally able to send it to production. The assembly and testing will follow in the near future.

One of the most important milestones in our case was the complete assembly of our system in as compact a form as possible. Although the system will not be installed in an aircraft yet, it is still important to us to make the whole thing as compact as possible. After several challenging and time-consuming iterations, we are happy with the final result.

In Review 2, we were again able to bring the audience up to date on the project. Both modules have again gained a lot of new knowledge since the last review and were able to make further theoretical or practical progress on the aircraft and the fuel cell system. More information can be found in our blog post.

We are proud to announce that the Swiss company EH-Group, which is based in Nyon, has entered into a partnership with us. The young company produces fuel cells and also develops complete systems. So they can support us with their know-how in our project in the best possible way.

On Friday morning, 5 November, Review 1 of the new e-Sling project took place. The two modules, hydrogen and aeroplane, had to present their progress of the last months in a 20-minute presentation each. Afterwards, all those present were allowed to ask questions. The presentations finally flow into the final grade of the focus project.

For two days, a group of focus students from e-Sling visited the Hydrogen Expo in Bremen. They were able to make important contacts there and secure one or two supports from larger industrial partners.

Over 200 people attended the RollOut of the e-Sling Team 2020/21, including sponsors, patrons, family members, team members and supporters. Besides the big unveiling of the plane, Dominic Gisin's speech and the flight raffle were definitely a highlight.

On the very first day of the new semester, we sat together as a new focus team and had our first meeting. Tasks were assigned, goals formulated and initial strategies explained. The first contacts were already made and we began to feel really comfortable in the team!