We bring liquid hydrogen into the air and prove with Liquid H2 that emission free aviation is the future.

After our successes with battery powered and gaseous-hydrogen propulsion systems, we take the next logical step: developing a propulsion system with liquid hydrogen. The energy density of liquid hydrogen is about three times as high as that of conventional aircraft fuels like kerosene, and therefore makes considerably longer flight routes possible.

We focus on the development of the system as a whole rather than on individual components. We take existing, proved components and rearrange them in a way that hasn't been done by anybody before. Not only the system design but also the structural integration into our carrier plane as well as safety are in the centre of our attention.

With our project Liquid H2 we aim to be the first hydrogen powered aircraft to cross the English Channel, with one stopover in Paris. This flight will mark an important milestone in emission free aviation, and will demonstrate the reach and practicability of our hydrogen propulsion system. We prove that sustainable flight with hydrogen is ready to shape the aviation of tomorrow.

Fuel cell system

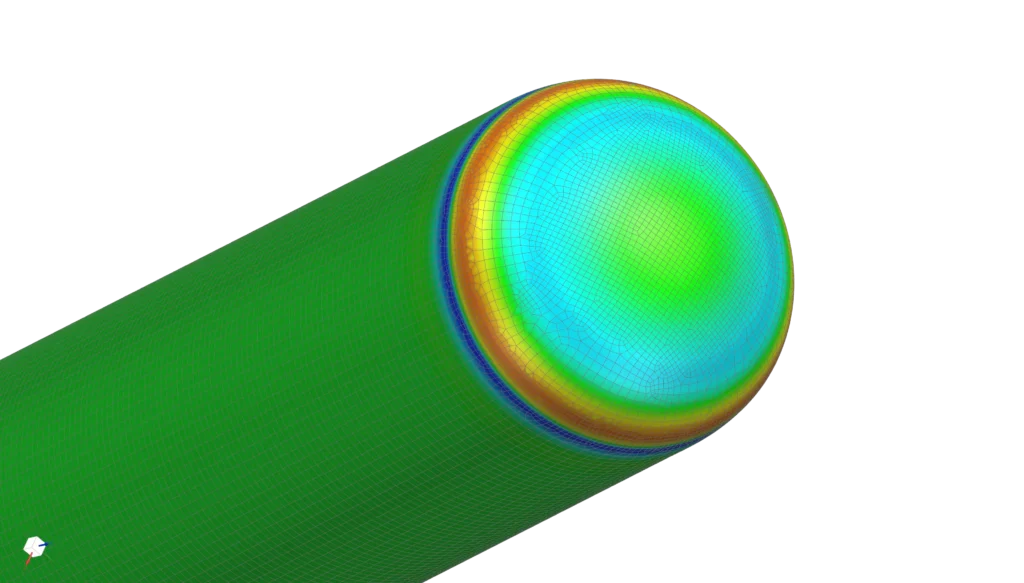

The liquid hydrogen tank stores hydrogen at a temperature of about -250°, and sets bigs challenges to its construction and material. To keep the hydrogen liquid, reliable isolation that keeps heat introduction at a minimum, is crucial.

As the low temperatures cause strong tensions of the material, contractions and extensions must be precisely taken into account while designing the tanks. The filling of the tanks poses further technical challenges: tension, temperature, and flow musst be controlled to ensure a safe operation.

Safety

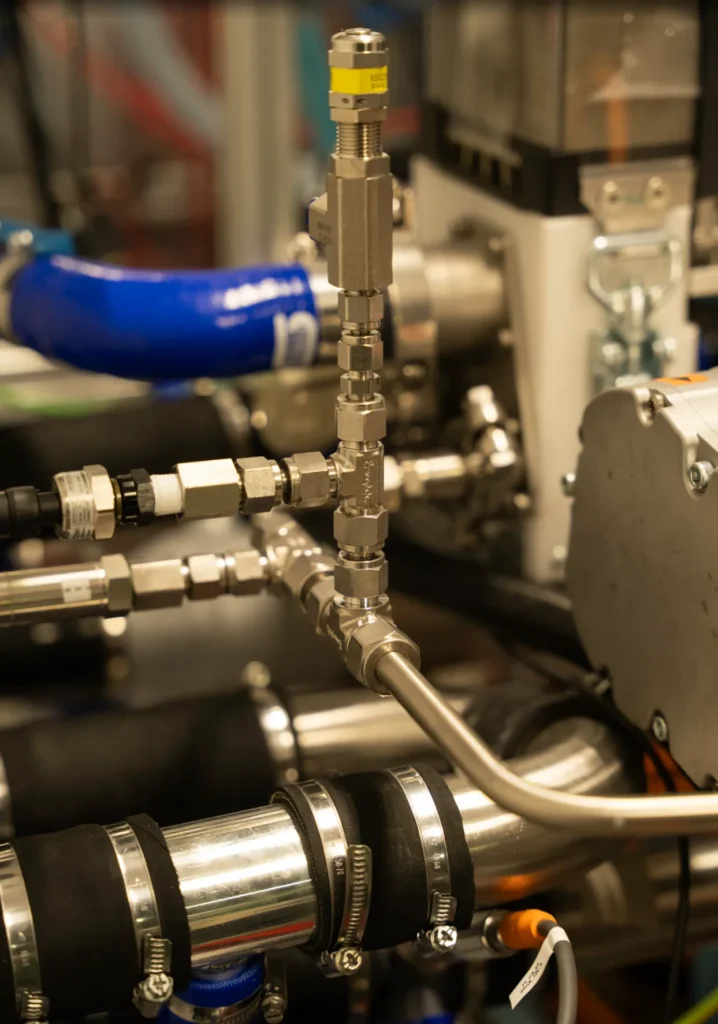

The fuel cell system is base on the one of the H2-Sling and is being refined. The goal is to reach higher efficiency and a better integration into the new propulsion concept with liquid hydrogen.

Inside the fuel cell hydrogen reacts with oxygen from the air, creating electric energy and heat. Various subsystems ensure a stable and safe operation by regulating temperature, pressure, and gas flows, creating the required conditions for a reliable and effective operation during flight.

HV-System

The fuel delivery system ensures a safe and controlled travel of the hydrogen from the tank to the fuel cell. Thereby it must withstand extremely low temperatures, while being as light and compact as possible.

One of the main tasks is the development of a heat exchanger, which heats the hydrogen using the waste heat of the fuel cell. An additional test stand will be built to test and optimise the liquid hydrogen system.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut

Wir wollen nicht nur innovative Antriebstechnologien entwickeln, sondern auch Studierenden die Chance geben, echte Praxiserfahrungen zu sammeln und aktiv zur klimaneutralen Zukunft beizutragen.

Technical Lead

Wir wollen nicht nur innovative Antriebstechnologien entwickeln, sondern auch Studierenden die Chance geben, echte Praxiserfahrungen zu sammeln und aktiv zur klimaneutralen Zukunft beizutragen.

Technical Lead

Wir wollen nicht nur innovative Antriebstechnologien entwickeln, sondern auch Studierenden die Chance geben, echte Praxiserfahrungen zu sammeln und aktiv zur klimaneutralen Zukunft beizutragen.

Technical Lead